It’s obvious that the COVID-19 pandemic has increased costs and pressure on after-sales support functions. As the pandemic began and has continued, pretty much everyone strives to limit contact with each other—it’s a safety issue.

Simultaneously, COVID-19 has resulted in device and machine owners demanding more self-serve capabilities, or the ability to execute remote repairs, even if they do it themselves with support. If a technician is needed on site, clients want the issue resolved quickly and expect a solution on the first visit. Service technicians also need to follow evolving COVID-19 safety protocols, which require training, and therefore, add to costs.

These calls are expensive. So, the pressure is on to make service better—and make it right the first time. Yet, our research with the IBM Institute for Business Value (IBV), “Empowered electronics service and support,” shows that more than 1 in 4 calls are not resolved on the first visit.

In 28% of repair tickets studied, companies were paying dramatically more than they should. There are multiple reasons for a second call, or even a second truck roll, and that’s taking away funding for other much-needed service enhancements. And that’s why the 28% finding pains me so much.

I have sat in almost every seat in the service and support center chain of command—including the one driving to customers to make repairs. Whether I was in a contact center, field delivery organization, or managing service operations, having access to data I could trust was critical.

Optimize the customer experience and save money

The more I knew about my customers, their devices, current issue, and service history, the better my chances were of resolving their issue. One thing I’ve learned is that it’s not impossible to both optimize the customer experience and save money for the organization.

As a matter of fact, when you use data from across your electronics enterprise, you can significantly improve service quality and improve root cause analysis. This is essential to managing client satisfaction, improving internal processes, and forecasting future warranty costs.

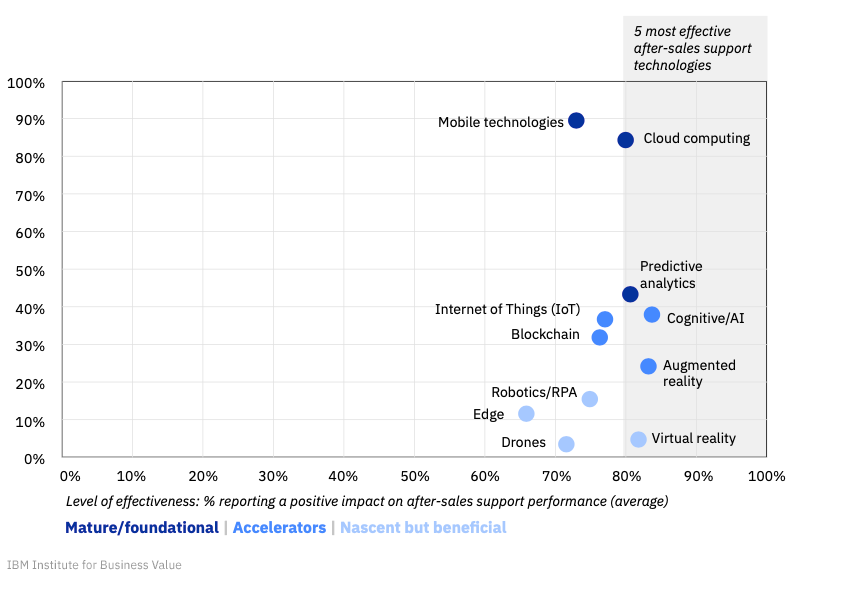

In our survey of electronics executives, predictive analytics was ranked the third most valuable technology, following only cloud and mobile tech (see, “Leaders of the pack”). This action-oriented approach to diagnosing and replacing issues before they become a problem brings the power of collected root cause analysis, service, repair, and wear data together in an efficient package for service experts.

Leaders of the pack

The most effective after-sales support technologies.

Data helps better diagnose device failure, bringing agents and field personnel to the right solution as fast as possible. Service data can also provide valuable insights into internal process or delivery problems, predict potential future warranty and service costs, and provide options or scenario analysis to mitigate cost increases.

Make data and service insights accessible to everyone

Electronics companies are responding to accelerating industry trends with new service-delivery models and exponential technologies to improve after-sales support functions. The best after-sales support organizations invest in technologies that get the data and service insights to front-line personnel and make them accessible across the organization. Data and technology must be tied together with collaboration across service partners or through a combination of delivery models to optimize results.

Service delivery managers need to continually focus on the details: Do I know where all my clients’ assets are installed? Does the technical support team have the skills needed to serve our customers? Do I have the right parts in the right places to support the expected failures? Even with the best-laid plans, there are often surprises.

When problems occur on the service side, it’s not simply a matter of fixing them. Sometimes you have only an outcome and you need to find the real problem first—this describes the detection-to-correction (D2C) cycle. Our research indicates that, across electronics machines and devices, when a large-scale problem occurs, the average D2C cycle is 32 days.

I faced a global quality issue on a new PC with higher-than-expected failure rates affecting hundreds of thousands of devices around the world. This could have been catastrophic to our clients and our service costs if we didn’t have the data we needed to respond early.

Product install data, device configuration, device failure data, and call center records allowed us to determine what was failing, where, and why. Service data and remote monitoring allowed us to predict and prevent failures, which achieved two critical service delivery goals: delight customers and reduce warranty and service costs. As we are reminded now, data for early detection and diagnosis helps to coordinate actions to contain the problem.

Manage the numbers

Transforming support and service functions won’t happen without a solid business case and getting there means managing the numbers. One of the more interesting aspects of our research is about a class of leading support and service teams and it’s worth considering how they are improving their businesses.

When we look at the technologies in our research, we find:

-

97% of those who have implanted augmented reality say it has improved the efficiency and quality of their after-sales support processes

-

90% apply mobile technologies in their after-sales support processes, making them the most prevalent in the industry

-

85% of those who have implemented cloud computing in after-sales support processes say it has reduced their time to execute

-

84% of those who have implemented cognitive/AI technologies rate them as most effective at improving electronics after-sales support performance

-

72% of those who have implemented predictive analytics in their after-sales support processes rate it as most effective at reducing the organization’s costs

Our research revealed how executives are planning to apply exponential technologies. They shared how their current implementations enhance aspects of after-sales support performance in terms of quality, performance, cost, and time saved.

While we didn’t have room in the report for all the details, we are happy to discuss it with you, based on your organization’s unique needs. The research also revealed how developing and applying insights from after-sales support data drives improvements throughout the organization. It’s possible to use tech to save money, improve customer satisfaction, and develop new agile processes across your organization.

For more details and a deeper perspective on how after-sales service organizations are transforming operations, see “Empowered electronics service and support: Creating data-driven human-technology interactions.” You can also reach out to me. I have over 30 years’ experience in after-sales support and I’m happy to share what I’ve learned with you.

Meet the author